Import Your Scan or Mesh

Effortlessly upload your scan or mesh data into MeshInspector to start the reverse engineering process. MeshInspector supports a variety of formats, including DICOM, STL, OBJ, PLY, and more. Whether you’re working with raw scan data or pre-designed meshes, you can bring your data into MeshInspector in just a few clicks.

- Fast Rendering: Instantly visualize your scan data, even for large files.

- Web & Desktop Access: Work seamlessly on desktop or access your projects on the go with MeshInspector’s web-based app.

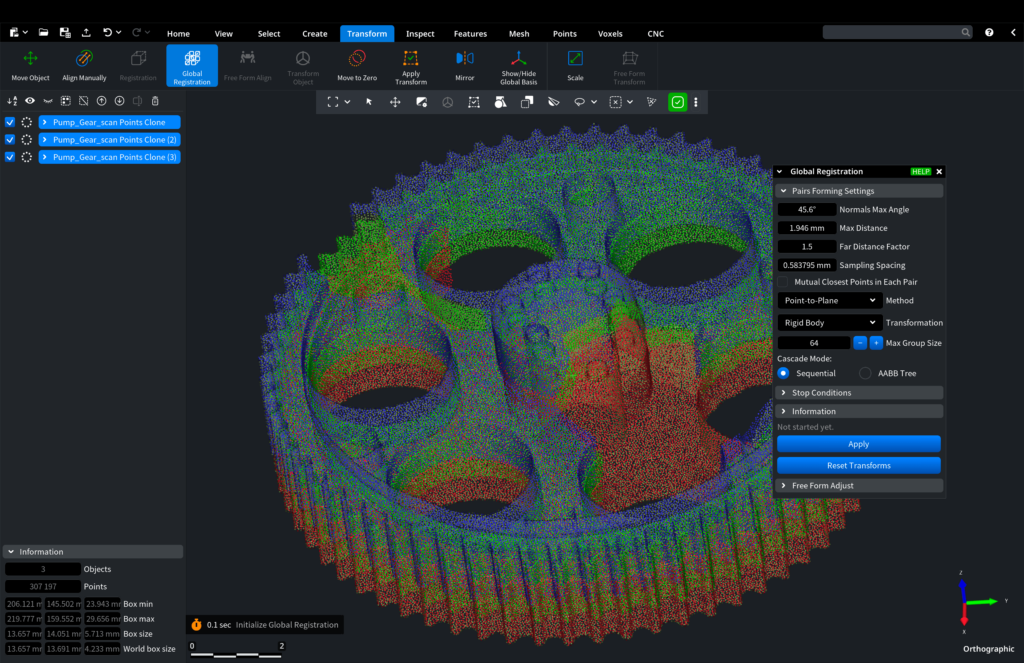

Align and Clean Up Scan or Mesh Parts

Before moving forward, ensure that all your scan or mesh parts are aligned properly. MeshInspector provides powerful alignment tools to help you merge multiple scans into a cohesive model.

- Manual Alignment: Select at least 3 corresponding points on each model part to manually align them with precision.

- Global Registration: Automatically align all scans in the scene with the Global Registration tool for fast, accurate results.

- Merge: Merge perfectly aligned scans in one.

By aligning and cleaning up your scan data early, you ensure a smooth and accurate reverse engineering workflow.

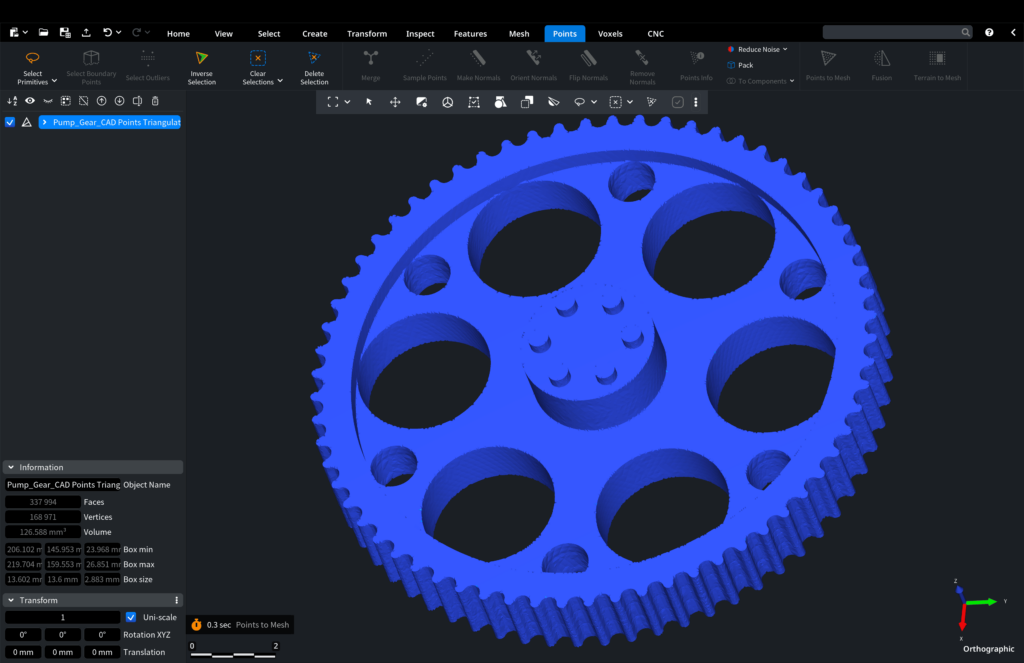

Convert Scan to Mesh

If you’ve uploaded raw scan data, the next step is to convert it into a detailed and accurate mesh model. MeshInspector offers powerful scan-to-mesh conversion tools to transform your data into a usable 3D mesh.

- Instant Conversion: Convert your scans into meshes in seconds using MeshInspector’s advanced algorithms.

- High Precision: Get clean, precise mesh models ready for further processing or design.

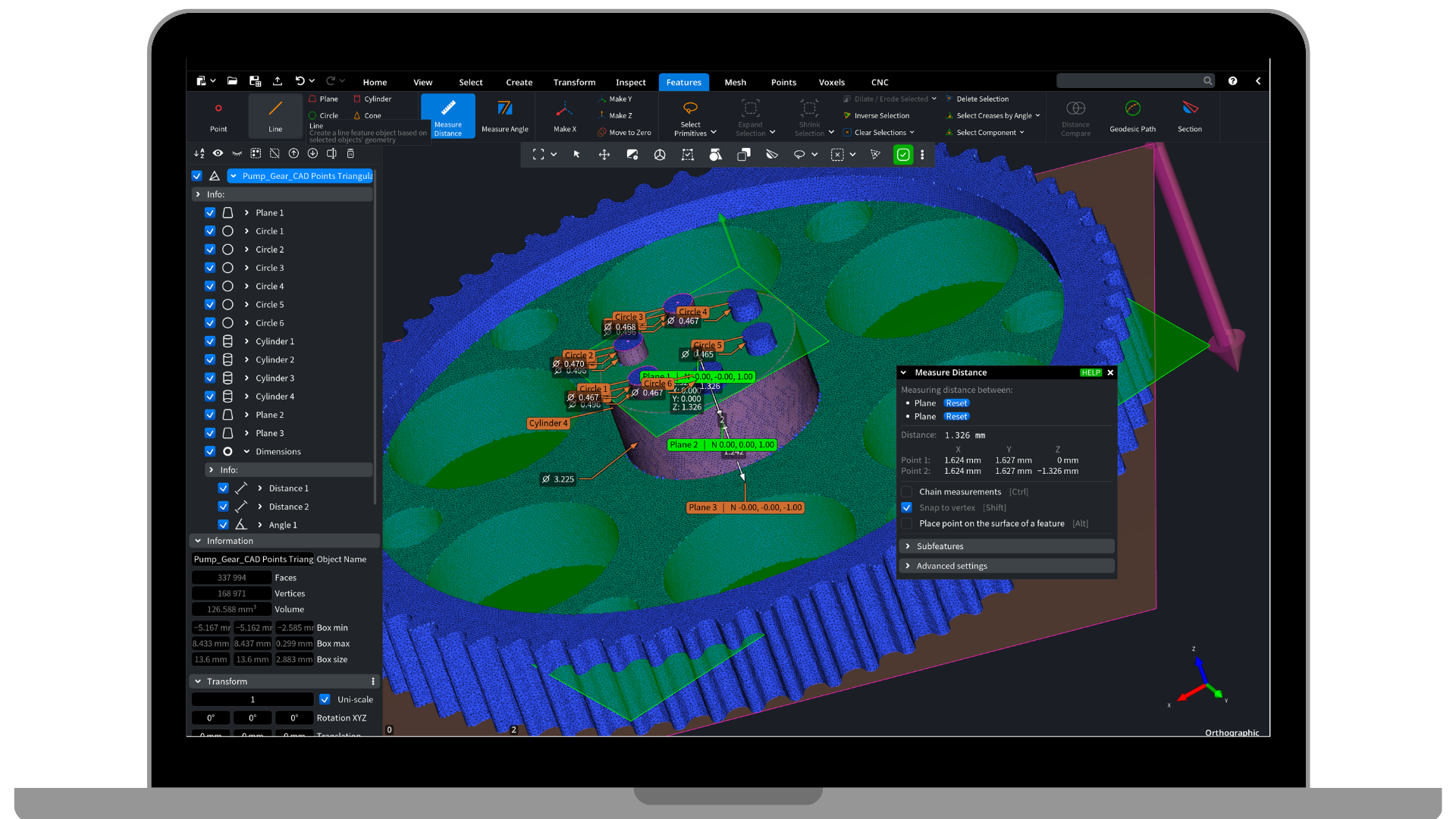

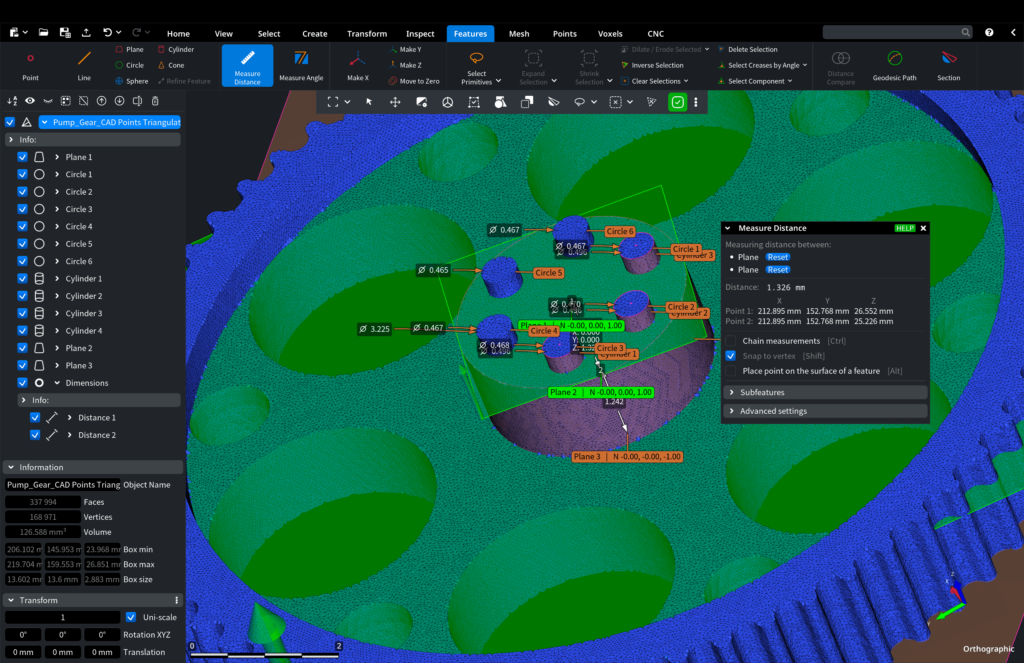

Create Features and Measure

Once your mesh is ready, MeshInspector allows you to create and measure critical features for reference in your CAD design.

- Create Features: Generate planes, circles, lines, and other features to aid in your design process.

- Measure Features: Measure distances, angles, and other parameters between these features to ensure accuracy and design fit.

Use these features to create accurate reference points for reverse engineering and as inputs for your CAD designs.

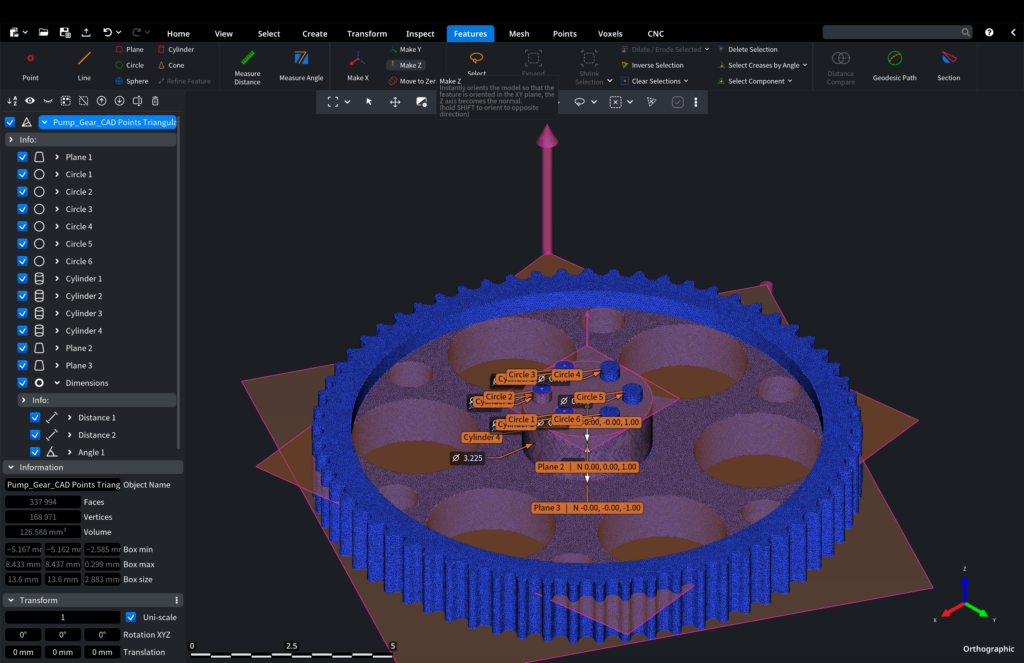

Align the Model by XYZ Axis Using Features

After generating features, you can use them to align your model accurately by the XYZ axis.

- XYZ Alignment: Use the features you’ve created to perfectly align the model in 3D space, making it easier to work with in further stages of the reverse engineering process.

This step ensures that your model is properly oriented and ready for detailed modifications or CAD integration.

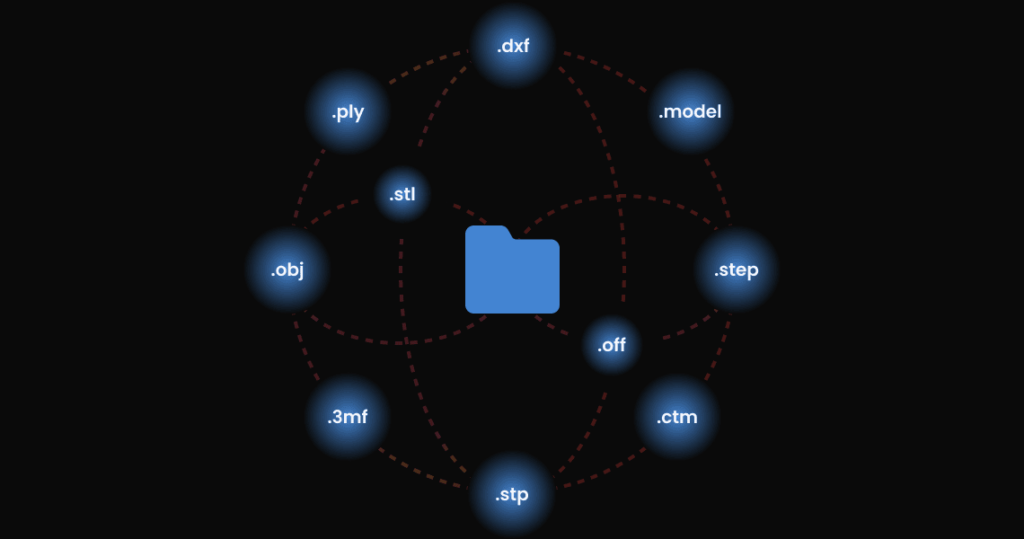

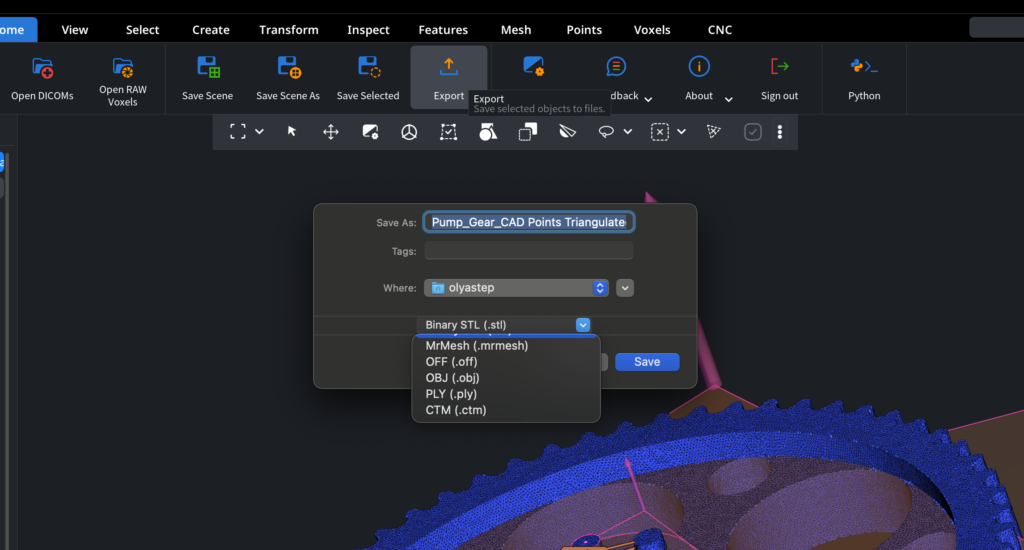

Export Your Mesh Model

Once your model is ready, MeshInspector makes it easy to export it for further use in CAD software or manufacturing. MeshInspector supports a wide range of export formats, including:

- Export Formats: .stl, .obj, .ply, .3mf, and more.

Your model will be optimized and ready for use in various applications, including 3D printing, CAD design, or further analysis.

FAQs

MeshInspector supports a wide range of formats, including DICOM, STL, OBJ, PLY, and more. This allows you to easily upload both raw scan data and pre-designed meshes to start your reverse engineering process.

You can use the Manual Alignment tool to select at least 3 corresponding points on each scan or mesh part for precise alignment. For faster results, use the Global Registration feature to automatically align all scans in the scene.

Yes, MeshInspector offers powerful scan-to-mesh conversion tools that allow you to transform raw scan data into high-quality, detailed mesh models in just a few clicks, ensuring precise and usable 3D models.

You can generate planes, circles, lines, and other features on your mesh model. These features can be used to measure distances and angles, serving as accurate reference points for your CAD designs and further modifications.

MeshInspector supports various export formats, including STL, OBJ, PLY and 3MF. This ensures your final model is compatible with CAD software, 3D printing, and other manufacturing processes.