Scan to Mesh.

Mesh to Production.

Fast. Reliable. Precise.

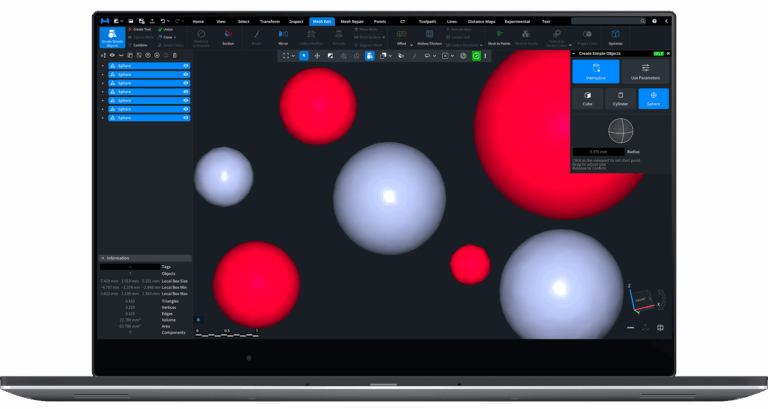

Prepare watertight 3D models with defined tolerances and QA reports, scale effortlessly with automation for massive meshes and point clouds, ready for printing, inspection, and simulation.

Join teams simplifying complex 3D data with MeshInspector’s editing, repair and inspection tools.

Why teams rely on MeshInspector

Working with complex 3D data often means fragile repairs, uncertain accuracy, and slowdowns when models grow. MeshInspector removes these barriers and gives teams a reliable foundation for printing, inspection, and simulation.

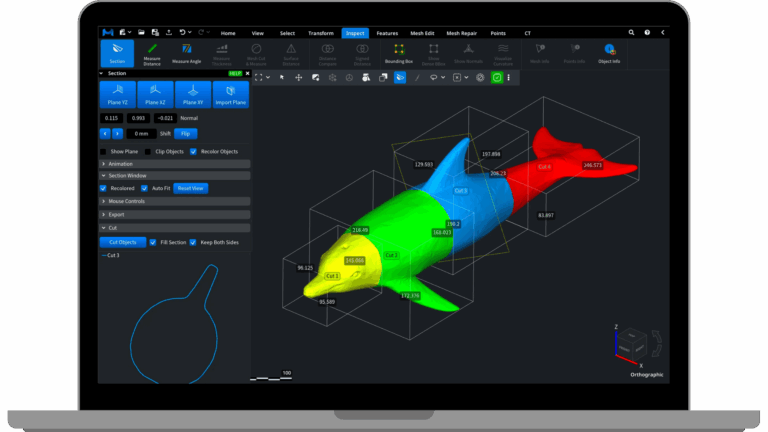

Verified results

Prevent costly errors by using tolerance controls, deviation maps, and QA reports to confirm geometry accuracy. This replaces unreliable visual checks with measurable proof.

Performance at scale

Process 10–50M+ triangle meshes, 50M–100M+ point clouds, and large CBCT datasets without stalls or crashes.

Automated workflows

Batch repetitive tasks with in-app Python and free up time for real work.

Cross-platform

Run MeshInspector natively on Windows, macOS, and Linux or in Web without limitations.

Seamless outputs

Import STEP and other common formats, handle meshes and polylines, and convert STL, OBJ, E57, PLY, and LAZ with correct units, axes, and deviation reporting.

Fair pricing

Get the core features you need at a reasonable cost, without paying for complex, high-priced tool suites.

Workflows tailored to your needs

Engineers

Service Bureaus

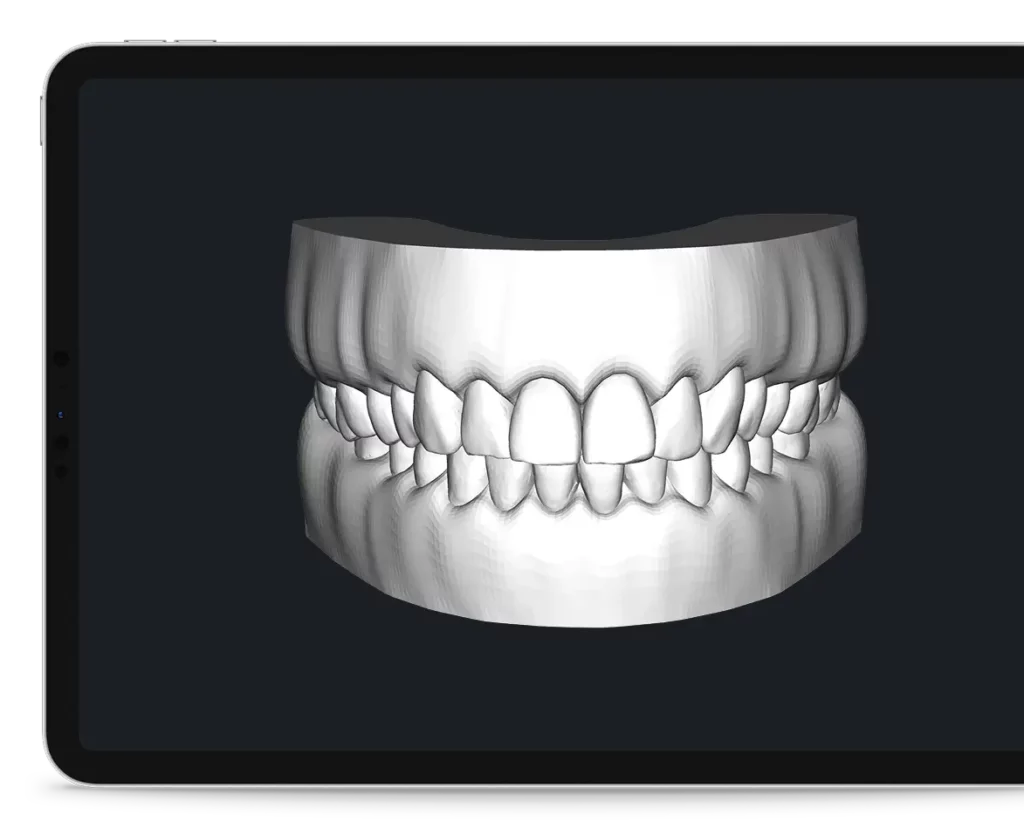

Dental Labs

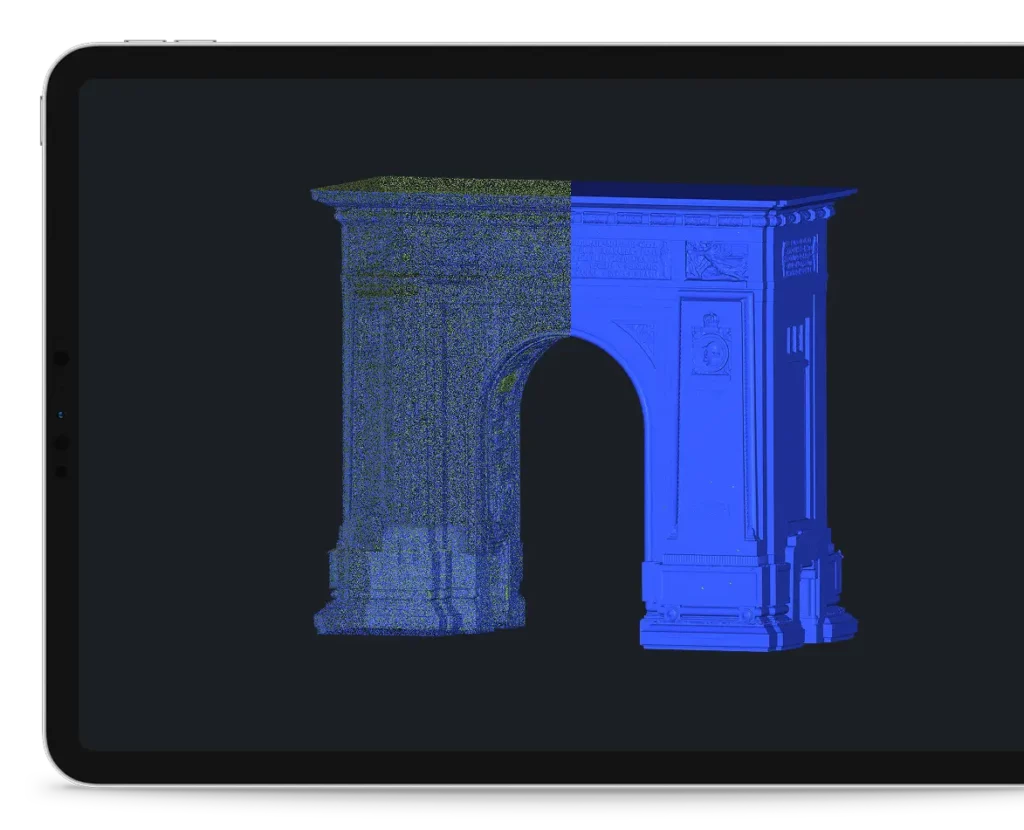

Scanning Professionals

Upload CAD File

STP/STEP files uploaded in the desktop app are converted into meshes locally on your machine.

Prepare for Production

Repair geometry and fill holes with one click using tolerance-based tools for watertight accuracy. Validate results with deviation color maps to ensure shape and detail integrity.

Engrave Text

Add serial numbers or identifiers directly onto the model.

Measure & Inspect

Measure features, distances, thickness, and gaps, and generate QA reports for reliable inspection.

G-code Preview

Preview G-code output to verify toolpaths before production.

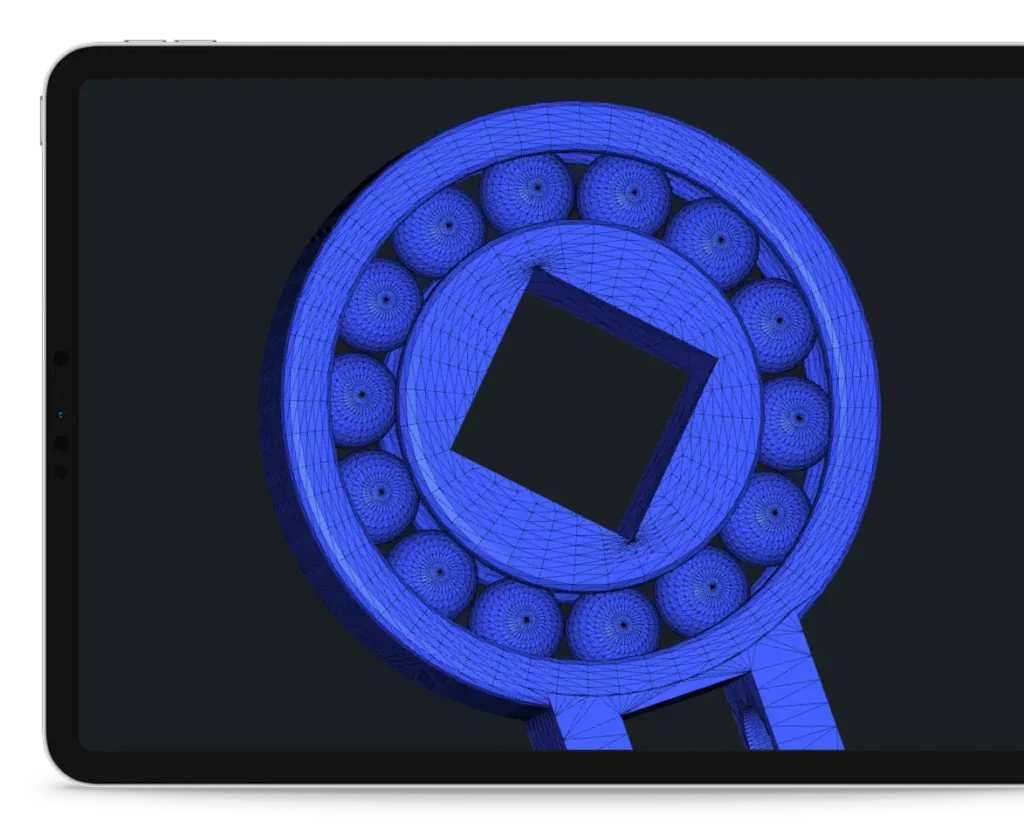

Scan Import

Import scan data from LiDAR, laser, structured light, or photogrammetry in standard mesh and point cloud formats (.stl, .obj, .ply, .e57, .las, .laz, etc.).

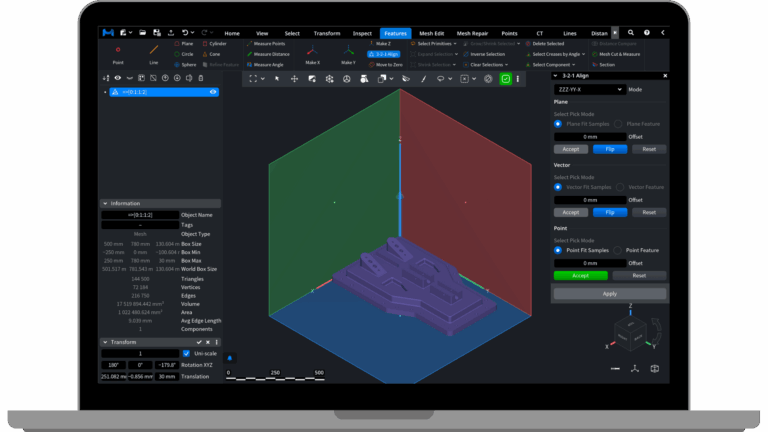

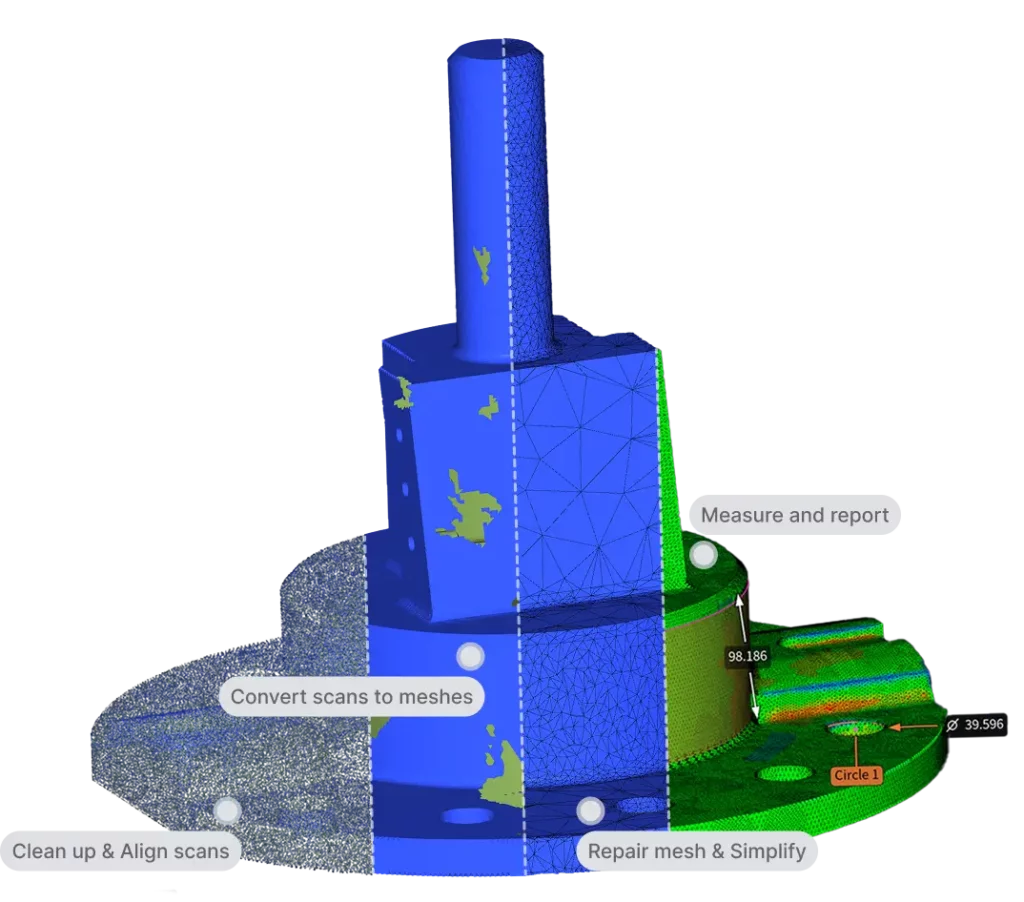

Clean & Align

Clean point clouds through noise reduction, outlier removal, and simplification, then align and merge scans into a single accurate 3D model.

Scan to Mesh

Generate watertight meshes from point clouds with efficient triangulation, fusion, or terrain-optimized algorithms, ready for delivery.

Repair & Measure

Identify and repair mesh errors with Mesh Healer, addressing holes, self-intersections, thin walls, and other issues, then verify results with tolerance settings and QA checks.

Export for Production

Export high-quality meshes in STL and OBJ formats for seamless manufacturing workflows and client delivery

Retainer Preparation

Design retainers and appliances through optimized digital workflows, applying offset adjustments to ensure accurate fit.

Repair & Redistribution

Inspect and repair dental models with advanced tools that detect defects, fill holes while preserving curvature, and maintain natural tooth geometry.

CBCT Processing

Visualize scan density, isolate bones, and extract bone meshes from CBCT scans for treatment planning.

Scan Cleanup

Easily remove unnecessary elements like braces to produce clean, accurate models.

Model Preparation & Labeling

Add bases and engraved or embossed patient data for immediate 3D printing.

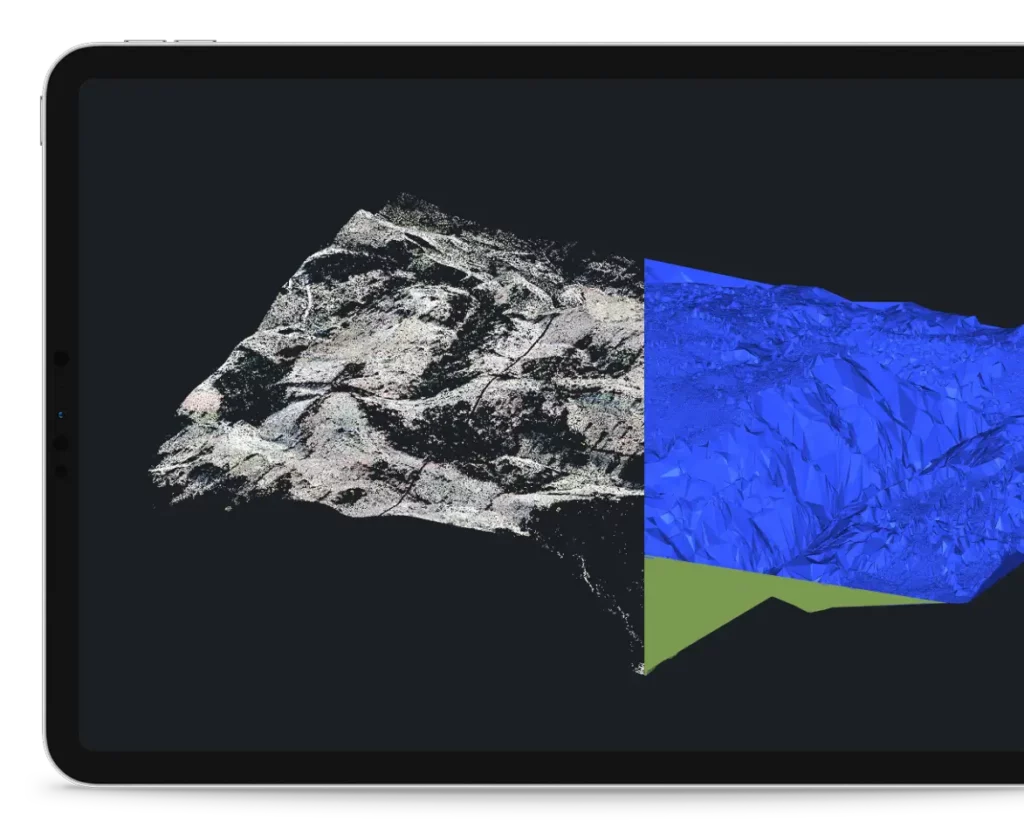

Work with Massive Datasets

Process 10–50 million+ triangle meshes and 50–100 million+ point clouds locally with full stability.

Сlean Up Point Сloud

Apply noise reduction, outlier removal, and data simplification while maintaining accuracy.

Align & Merge

Combine multiple scans into one model with manual, pairwise, or global alignment.

Convert to Mesh

Transform raw point clouds into watertight meshes optimized for analysis, simulation, and 3D printing.

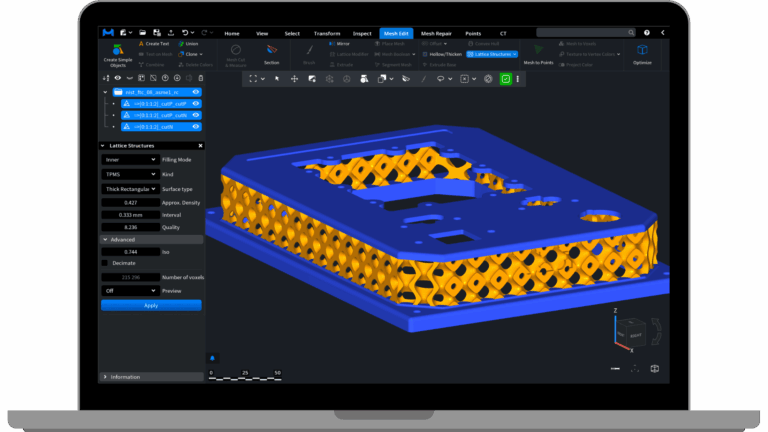

Edit & Repair Meshes

Fix geometry and prepare accurate, production-ready meshes.

User Testimonials

See how MeshInspector has improved workflows for professionals worldwide.

Gabriele Impellizzeri

R&D Manager

MeshInspector significantly helped us in streamlining all of our 3D printing mesh modeling tasks thanks to its ability to fix, smoothly decimate and operate on our large-size lattice meshes in a fast and effective way.

Erick Geisler

Chief Technical Officer

"MeshInspector has completely transformed our workflow. It's faster, more efficient, and offers incredible value. The responsiveness of the development team and the quality of the software have given us a significant edge over our competitors."

Peter Sekula

Chief of Operations | Matterfield

"MeshInspector proves invaluable for 3D artists with its swift decimation and powerful Python API, streamlining workflows and enhancing efficiency. Its automation capabilities render it indispensable in the realms of gaming and VFX."

Daniel Gelep

3D Scanning Representative, Susteni AS

"It's the fastest program I\'ve used so far, and I can now do 150 scans in just 2 days instead of 1.5 weeks."

Ruedger Rubbert

Chief Technology Officer, Brius Technologies Inc

"With MeshInspector MeshLib we were able to automate many of our workflow processes, thanks to its advanced, modern, and efficient dental and geometry oriented algorithms, covering many of our orthodontic-related tasks: CT and intraoral scan segmentation, voxel and Boolean operations, editing, aligning, visualization, inspection, and import/export of mesh objects. We use the versatile MeshInspector MeshLib API, both in production and R&D for fast prototyping and testing of our ideas."

FAQs

MeshInspector is entirely cross-platform and accessible on all devices through web browsers, as well as through desktop applications compatible with Windows, MacOS, and Linux.

Certainly, you can accomplish that using a mobile web browser. Nevertheless, for the best user experience, we recommend downloading and installing the desktop version after signing up.

MeshInspector supports importing and exporting 3D models for seamless integration with other software in your workflow.

It handles multiple data types, including meshes, point clouds, volumetric data, lines, distance maps, and G-code.

A complete list of supported file formats is available in our Knowledge Base.

Yes. We take data security seriously. Files opened in MeshInspector’s web version are processed and stored in your browser’s local memory. In the desktop app, all files are handled and stored locally on your computer’s memory.

Yes, we offer a free trial so you can take your time to explore the application’s features. For pricing details and subscription options, please visit our pricing page.

Our application is designed to be user-friendly for both beginners and experts. You can get started with basic functions and gradually explore more advanced features as you become comfortable.

Check out the solutions here for step-by-step guidance on resolving login issues. If problems persist, contact us at support@meshinpector.com for assistance.