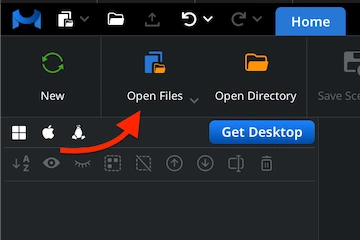

Opening STEP Files

We start by launching the MeshInspector program. When the UI opens, go to the 'Home' tab and select ‘Open Files’. Choose the STEP file that you plan to convert into the OBJ format.

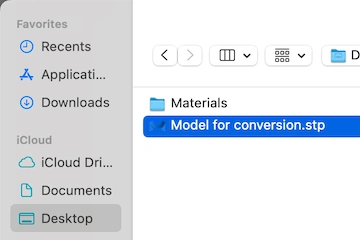

Browsing STEP Files

A file selection dialog will appear. Browse to your .step (or .stp) file, highlight it, and confirm the selection by clicking ‘Upload’ or by double-clicking the file name, as usual.

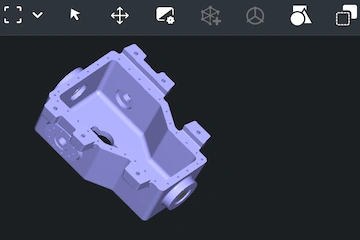

Viewing STEP Files

As soon as the file is imported, the STEP model will appear in the main viewport, with every detail retained. The STEP model is now totally ready for your inspection and subsequent export.

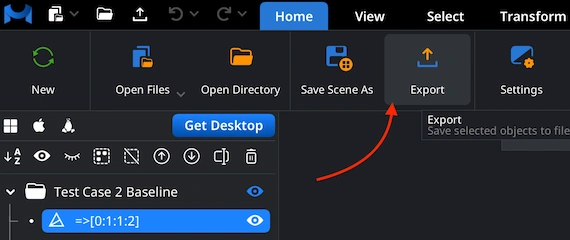

Exporting Components

When you can see that your STEP model is ready for conversion, decide exactly which elements you want to include in the export. In the Scene Tree, select the component you wish to change, right-click it, and choose ‘Export’.

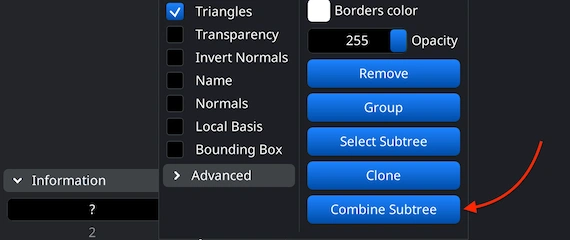

Combining for Export

If your file contains several parts, you can merge them into a single object. In the Scene Tree, select all objects, right-click, and choose ‘Group’. Then right-click on the new group and select ‘Combine Subtree’ to unite the components.

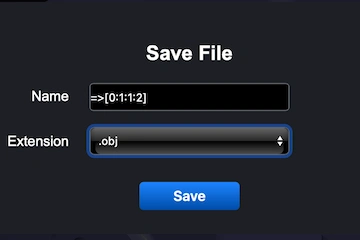

Setting OBJ Format

After clicking the ‘Export’ button on the top toolbar, the ‘Save File’ dialog will appear. You can rename your model if necessary, then open the ‘Extension’ dropdown list. Choose .obj as the target format of choice. Once confirmed, MeshInspector will quickly carry out the conversion from your STEP file, generating an OBJ object ready for use.

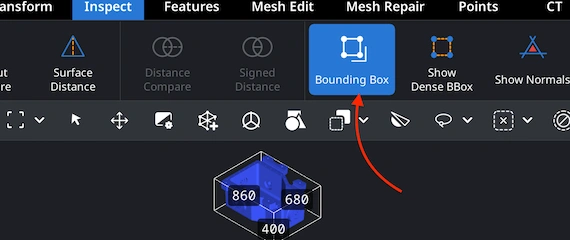

Inspecting the OBJ Size

After exporting your .obj file, open it in MeshInspector to verify that the conversion went as expected. Navigate to the ’Inspect’ tab. There, enable ‘Bounding Box.’ This feature displays the model’s full dimensions, allowing one to confirm that the scale and proportions are correct.

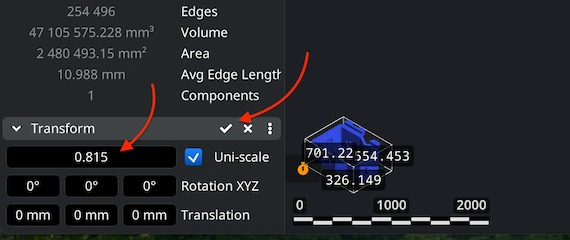

Adjusting the OBJ Scale

If a model appears unacceptable in terms of its size, go to the ’Transform’ panel and adjust the Scale slider until the size looks right. Once satisfied, apply the change by clicking the checkmark icon. This ensures your STEP-to-OBJ conversion produces relevant proportions and volumes.

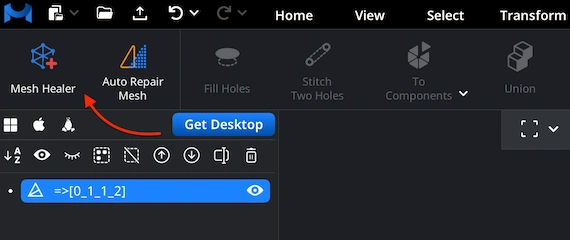

Finding ‘Mesh Healer’

Before completing your STEP-to-OBJ conversion, it is important to make sure the mesh is clean and structurally sound. Go to the ’Mesh Repair’ tab and open ‘Mesh Healer’ from the top-left corner. This tool automatically analyzes the geometry and detects imperfections. It prepares your OBJ for a mesh fixing round. Doing so at this stage helps prevent potential issues that could otherwise lead to errors or wasted time.

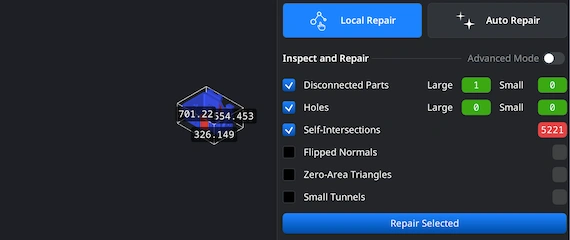

Fixing the OBJ

Within the ’Mesh Repair’ tab, ‘Local Repair’ identifies and corrects typical geometry problems such as disconnected parts, holes, self-intersections, flipped normals, zero-area triangles, or small tunnels. For additional validation, enable ‘Thin Walls’ and ‘Undercuts’ to check printability. If the mesh is heavily damaged, you can also use ‘Auto Repair’ to rebuild the model from scratch automatically to ensure a clean OBJ.