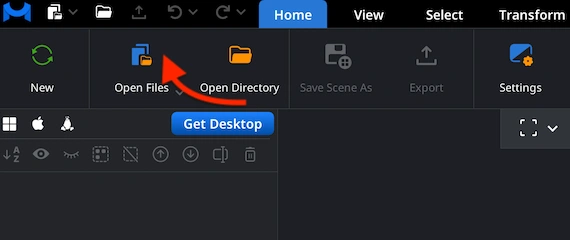

Opening an NC File

Under the ’Home’ tab, click ’Open Files.’ This option lets you load your NC file into the MeshInspector program for inspection. After you select the file, the viewer imports the complete toolpath and prepares it for visualization, regardless of how large your projects are or how many tool movements they contain.

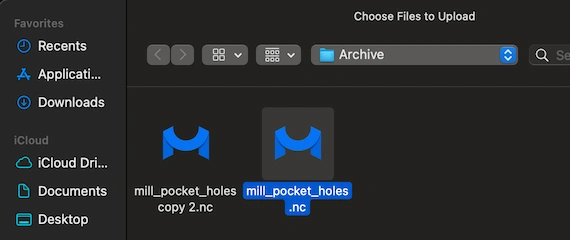

Selecting an NC File

Click ’Browse.’ Navigate to the folder where your NC file is stored. Then either double-click the file or confirm the selection with Upload. The MeshInspector program for reading NC files can also open entire folders containing multiple operations, which is useful when a workflow is split into components.

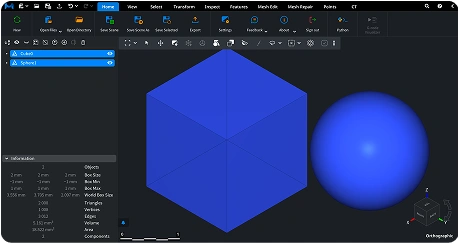

Viewing an NC File

After the NC file is loaded, its toolpath appears in the viewport. You can inspect the machining trajectory from any angle. Rotation of the view is possible by dragging with the left mouse button or employing one-finger touchpad gestures. Pan the scene by holding the right mouse button or sliding two fingers on a touchpad. Zoom in or out with the mouse wheel or a pinch gesture. To tilt, hold Ctrl and drag with the left mouse button. These controls let you examine rapid positioning moves, cutting passes, vertical Z transitions, and the overall machining strategy represented in the NC program.

Checking Toolpath Extents

In the ’Inspect’ tab, you can activate ’Bounding Box’ or ’Show Dense Box’ to examine the spatial limits of your NC toolpath. Bounding Box outlines a simple axis-aligned frame that surrounds the selected motion path, giving you a clear overview of its overall footprint. Show ‘Dense Box’ computes a tight and geometry-aware envelope that follows the toolpath closely.

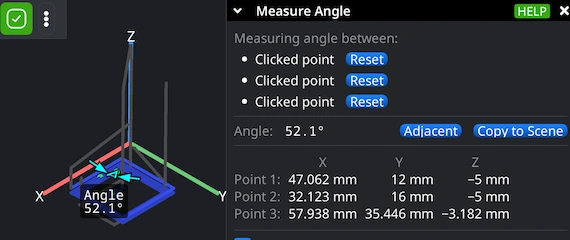

Measuring Angles on NCs

MeshInspector lets you analyze geometric relationships inside an NC with precision. To measure an angle, open the ’Measure Angle’ tool in the ’Inspect’ tab and select three points along the trajectory. After the third point is placed, the viewer immediately computes the angle and presents the result in both the viewport overlay and the measurement panel.

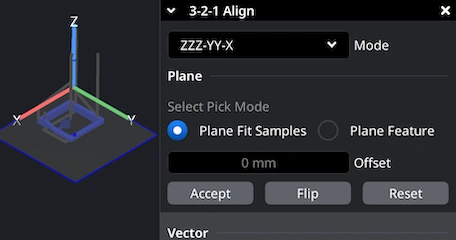

Aligning an NC Toolpath with 3-2-1 Align

The ’3-2-1 Align’ tool in the ’Transform’ tab helps you place an NC toolpath into a stable and predictable coordinate orientation. This method is widely used to define positioning through three sequential references, i.e., primary plane defined by three points, a secondary direction set by two points, and a final axis constraint determined by one point. In MeshInspector, this alignment workflow lets you correct programs exported with unexpected rotations or offsets.